Przemysł farmaceutyczny / Biotechnologie

Monitoring procesów fermentacji, odzyskiwania oraz suszenia rozpuszczalników, analizator termograwimetryczny - spektrometr mas (TGA-MS), analiza oddechu, monitoring procesów sterylizacji NO2 oraz EtO, kontrola procesów suszenia i odzyskiwania rozpuszczalników

z materiałów filtracyjnych, monitoring koncentracji substancji zanieczyszczających w procesach "clean-in-place" (CIP)

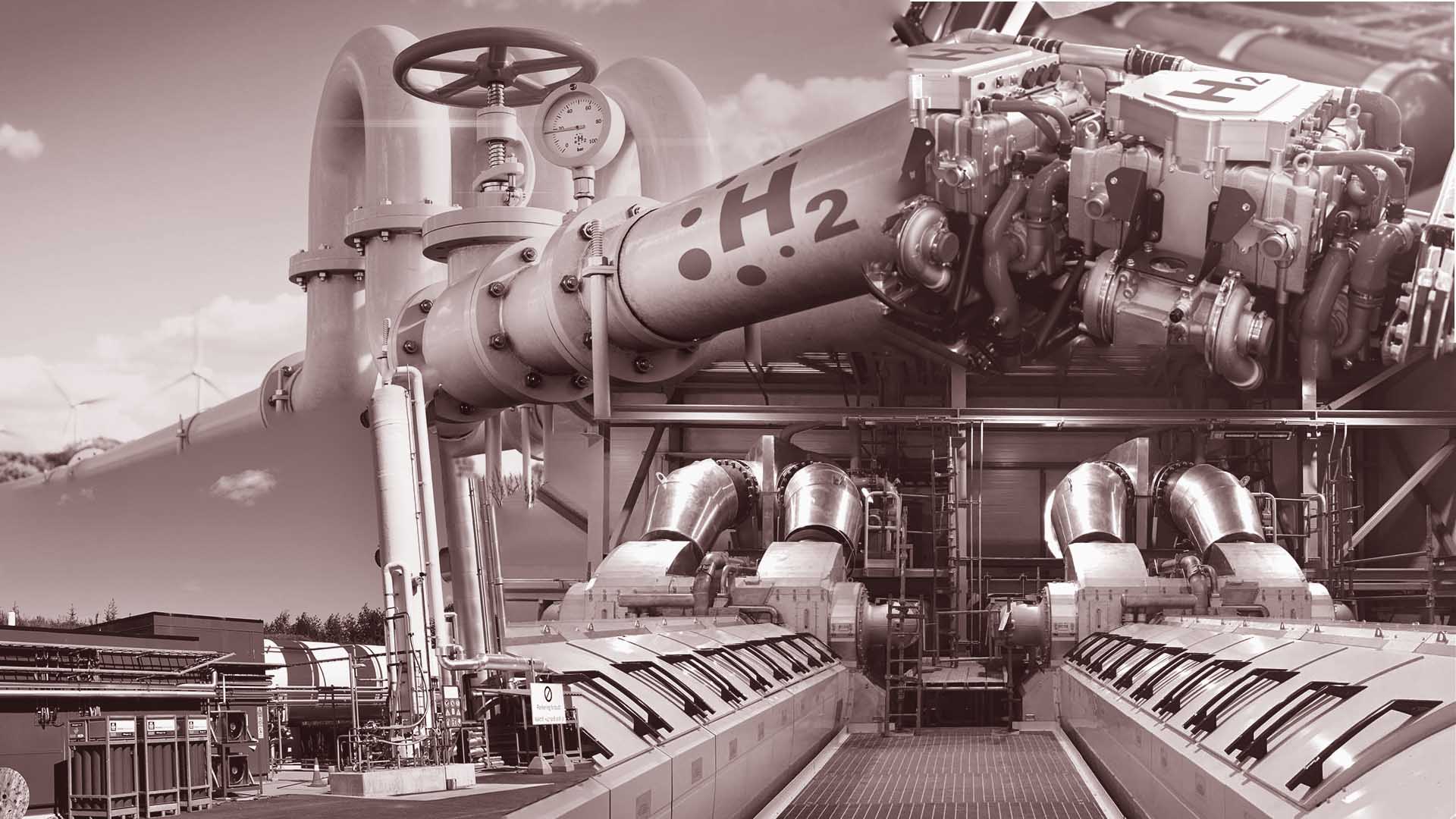

Wytwarzanie energii / Biopaliwa

Analiza procesów pyrolizy oraz spalania biopaliw, produkcja etanolu, badania ogniw paliwowych, wytwarzanie wodoru, obliczanie wartości BTU gazu ziemnego oraz biopaliw, monitoring procesów zgazowania, analiza odnawialnego gazu ziemnego

Analiza gazów

Analiza gazów uwalnianych (EGA), monitoring czystości gazów, analiza wodoru i helu / deuteru, analiza gazów resztkowych (RGA)

Produkcja metalurgiczna

Tlenowy proces konwertorowy (BOP), procesy wielkopiecowe, stacje mieszania gazów, procesy odwęglania tlenem w próżni (VOD)

Klastry / Biomolekuły / Nanocząstki

Analiza jonów o dużej masie cząsteczkowej,

Selekcja masowa oraz osadzanie jonów

Badania materiałowe

Kataliza, ablacja laserowa, badania nad odgazowaniem materiałów, rozpraszanie jonów, Spektroskopia Mas Jonów Wtórnych SIMS, temperaturowo programowana desorpcja TPD, analizator termograwimetryczny - spektrometr mas (TGA-MS) w badaniach materiałowych

Branża półprzewodnikowa

Litografia ultrafioletowa w próżni (VUV), epitaksja z wiązek molekularnych (MBE), trawienie plazmowe, chemiczne osadzanie z fazy gazowej (CVD) oraz chemiczne osadzanie z fazy gazowej ze wspomaganiem plazmowym (PECVD), badanie efektywności skruberów

Przemysł petrochemiczny

Produkcja amoniaku, metanolu, etylenu, tlenku etylenu, polietylenu, wytwarzanie wodoru,

obliczanie wartości BTU gazu ziemnego / gazu zasilającego, petrochemiczny gaz syntezowy

Badania środowiskowe i atmosferyczne

Monitoring powietrza, chemia atmosfery, monitoring benzenu, monitoring emisji, pochodnie, badanie efektywności skruberów, analiza wody

Kataliza

Analiza gazów uwalnianych (EGA), Spektroskopia Mas Jonów Wtórnych SIMS, temperaturowo programowana desorpcja TPD

Przemysł produktów spożywczych i napojów

Analiza gazów stosowanych w procesach technologicznych: inertyzacja, nasycanie dwutlenkiem węgla, konserwacja żywności oraz napojów, ekstrakcja wysokociśnieniowa, monitoring atmosfer ochronnych i procesów pakowania oraz wiele innych

Przemysł chemiczny

Monitoring oraz analiza gazów w procesach technologicznych: np. produkcja kwasu azotowego, synteza amoniaku oraz wiele innych

Przemysł cementowy

Monitoring gazów w procesów technologicznych: piec obrotowy, kalcynator, podgrzewacz, silosy z węglem, młyn węglowy, instalacja odazotowania (kontrola NOX oraz poślizgu NH3 do spalin)